Hot rooms, rising electric bills, and techs speaking in jargon—many homeowners face the same frustrations. A surprising share of issues stems from one gap: not knowing the essential air conditioner components or how they work together. When you understand the compressor, condenser, expansion device, evaporator, blower, filters, and controls, you can catch problems early, speak clearly with HVAC pros, and choose upgrades that matter. In the pages below, you’ll get plain-language explanations, quick checks you can do, and practical fixes that boost comfort and efficiency.

The Refrigeration Loop: Compressor, Condenser, Expansion Device, and Evaporator

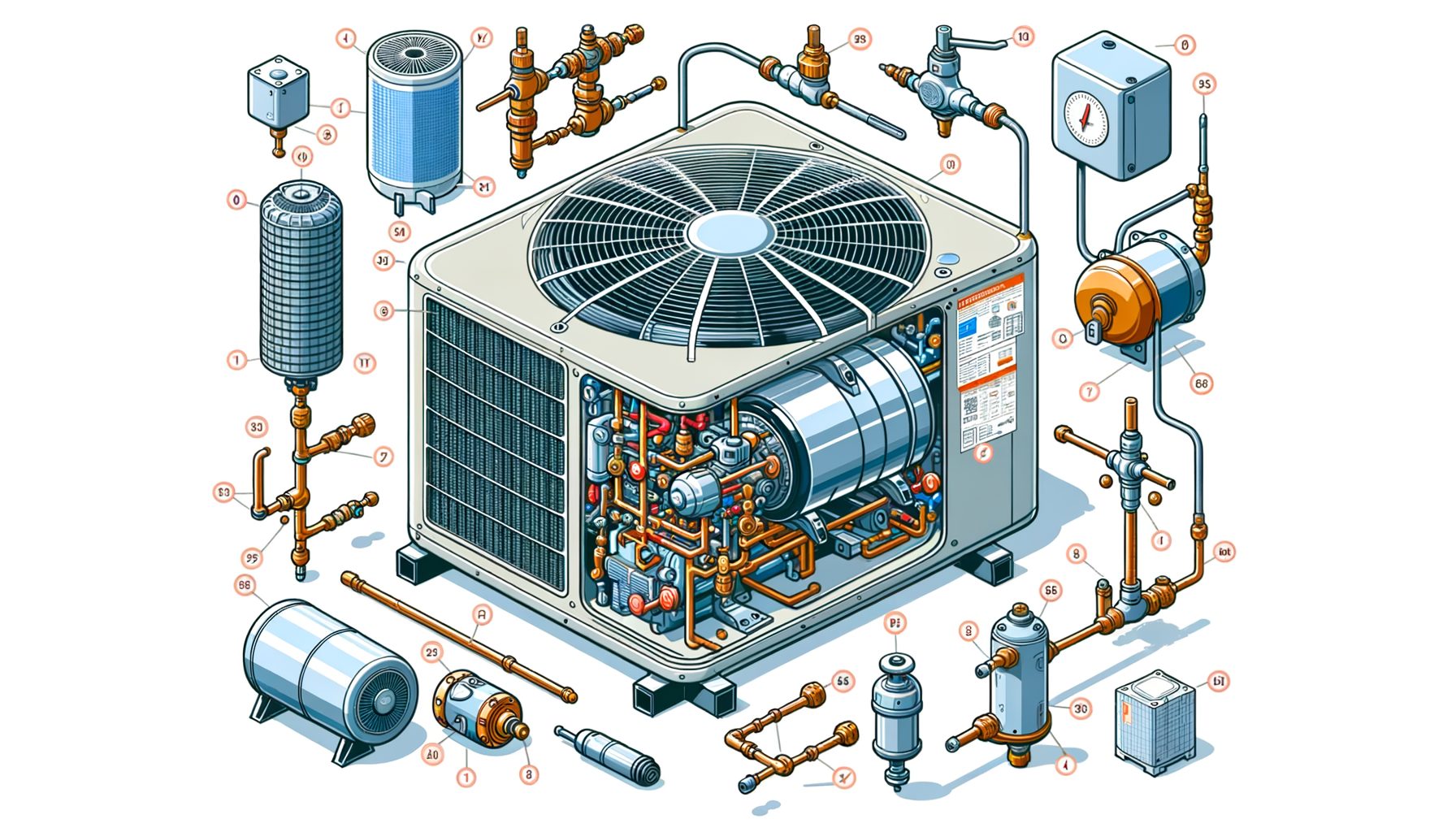

Modern AC systems—split, window, or ducted central—move heat with a sealed refrigerant circuit. Four core parts do the heavy lifting: compressor, condenser, expansion device, and evaporator. Imagine refrigerant as a courier running a loop that picks up indoor heat and drops it off outdoors.

At the heart sits the compressor. It boosts refrigerant pressure and temperature, turning low-pressure vapor into hot, high-pressure vapor. Because compression consumes a lot of energy, the compressor’s condition shows up directly on your bill and in your cooling capacity. Watch for short cycling, tripped breakers, loud humming, or warm supply air. Sizing matters as well—match the compressor to the load to control humidity better and avoid rapid on/off cycling.

Next stop: the condenser coil, usually outside. A fan pulls outdoor air across the coil so refrigerant can dump heat and condense into a high-pressure liquid. When fins are clogged by dust, leaves, or lint, heat rejection nosedives. A simple routine helps: cut power, gently rinse the coil from the inside out, and keep 60–90 cm (2–3 feet) of clearance around the unit. Bent fins can be straightened with a fin comb. On scorching days, a clean condenser often determines whether you get crisp cooling or lukewarm air.

After condensing, the high-pressure liquid meets the expansion device—TXV, EEV, or capillary tube. That metering device regulates flow and drops pressure. As the pressure falls, part of the liquid flashes into vapor, cooling the mixture. If the valve sticks or is misadjusted, the evaporator may be starved (weak cooling, icing) or flooded (unstable operation, extra energy use). Then this: small adjustments by a trained tech can stabilize temperatures and protect the compressor.

Cold, low-pressure refrigerant then enters the indoor evaporator coil. Warm indoor air blows across, heat is absorbed, and the refrigerant fully evaporates. Moisture condenses on the coil and drains away. Dirty or iced coils choke airflow and crush performance. Typical culprits include clogged filters, a low refrigerant charge from a leak, or a failing blower. Expect weak airflow, musty odors, or puddles from a clogged drain. Regular filter changes and annual coil inspections cost little and safeguard all four components for longer life.

Airflow and Indoor Comfort: Blower, Filters, Ducts, and Drainage

Great refrigeration with poor airflow still yields poor comfort. The indoor fan (blower motor) must move the right amount of air across the evaporator and through the duct system. When airflow drops below design, coils can freeze, ducts may sweat, rooms go uneven, and energy use climbs. A variable-speed (ECM) blower keeps airflow steadier across changing static pressure and often runs quieter—comfort improves, and so does efficiency.

Filters serve as the first line of defense. A too-restrictive filter—or one that’s never changed—strangles airflow. Check monthly in peak season and replace or wash every 1–3 months; homes with pets or dust may need more frequent changes. Balance particle capture and airflow: MERV 8–11 suits most households. Very high MERV ratings can overwork older blowers unless the system is designed for them or the filter cabinet is upgraded. Keeping filters clean can trim energy use and prevent debris from coating coils and fans.

Ductwork, the quiet contributor, often causes the loudest complaints. Field studies show leaky or poorly insulated ducts can waste 20–30% of conditioned air, turning cool air into attic heat and forcing longer runtimes. Hot or cold spots, whistling, and dusty rooms are common clues. A professional duct test and sealing with mastic or metal tape (avoid cloth “duct tape”) delivers fast comfort gains. For readers using ductless mini-splits, the logic is similar: clean the indoor unit’s filters, keep clear intake and discharge for wall cassettes and outdoor units, and match fan speeds to room size.

Drainage keeps humidity in check. As the evaporator cools air, condensate flows to a drain pan and line. Lines can be clogged by algae or debris, leading to leaks, shutdowns, or musty odors. A simple homeowner step: pour a little diluted vinegar down the condensate drain during the cooling season to discourage growth. Adding a float switch can shut the system off before overflow damages floors or ceilings. Hear gurgling or see water around the air handler? Turn the unit off and clear the drain promptly.

Supply and return balance also matters. Blocked returns, too many closed supply registers, or furniture crowding vents can disrupt pressures and create noise. Keep returns clear, leave most supply vents open, and vacuum registers several times a year. Good airflow doesn’t just improve comfort—it shields the compressor and keeps energy costs predictable.

Smart Controls, Electrical Parts, and Efficiency Ratings

Controls make sure mechanical parts run only when needed—and as efficiently as possible. The thermostat calls for cooling; the control board, contactor, and relays route power to compressor and fans. Capacitors store energy so motors start and run smoothly. If the outdoor unit clicks but won’t start, or motors hum and stall, a failed capacitor or contactor is a common, inexpensive fix for technicians. Electronics dislike surges and heat; a surge protector and shading for outdoor units can extend component life.

Smart thermostats and zoning add comfort with measurable savings. Allow temperatures to rise by 1–2°C (2–4°F) when you’re away, then precool before you return—runtime drops without sacrificing comfort. Utility programs and studies often show savings in the single to low double digits, depending on climate and behavior. Features such as geofencing, scheduling, occupancy sensing, and humidity control make cooling feel both smarter and thriftier. Uneven temperatures from room to room? Zoned dampers with separate thermostats can direct air where it’s needed, provided airflow through the coil remains within design limits. Well, here it is: design the zones right, or comfort suffers.

Efficiency ratings help with apples-to-apples comparisons. SEER/SEER2 measure seasonal cooling efficiency in many regions; EER rates fixed conditions; in Europe and elsewhere, SCOP or CSPF indicate seasonal performance. Variable-speed inverter compressors modulate output to match the load, improving part-load efficiency and reducing noise. If your system short cycles or swings widely in temperature, a right-sized inverter system can feel like a total reset.

Refrigerant choice influences performance and future serviceability. Legacy R‑22 has been phased out in many countries due to ozone depletion. R‑410A became the standard, yet its high global warming potential is driving phase-downs. Newer lower-GWP options—R‑32, R‑454B, and in some applications natural refrigerants like propane (R‑290)—are entering the market. Technicians need proper training for A2L or A3 refrigerants, and local codes govern installation. What’s interesting too: asking about refrigerant availability, environmental impact, and service support in your region can steer you toward the best long-term option.

| Refrigerant | Status (typical) | Approx. GWP (100-yr) | ODP | Flammability Class | Notes |

|---|---|---|---|---|---|

| R‑22 | Phased out/legacy | ~1,810 | Yes | A1 | Ozone-depleting; service involves reclaimed stock only in many regions |

| R‑410A | Common but phasing down | ~2,088 | No | A1 | Widely used; high GWP driving phase-downs |

| R‑32 | Growing use | ~675 | No | A2L | Higher efficiency potential; mildly flammable |

| R‑454B | Newer adoption | ~466 | No | A2L | Lower GWP replacement path for many R‑410A systems |

| R‑290 (Propane) | Niche HVAC use | ~3 | No | A3 | Very low GWP; higher flammability, strict safety rules |

Q&A: Fast Answers to Common AC Questions

What are the four main components of an air conditioner?

Compressor, condenser, expansion device (TXV/EEV/cap tube), and evaporator. Together they move heat from indoors to outdoors by compressing, condensing, expanding, and evaporating refrigerant.

How often should I change my air filter, and what MERV should I use?

Check monthly during heavy use and replace every 1–3 months. For most homes, MERV 8–11 balances filtration and airflow. Higher MERV can be used if your system is designed for it or you upgrade the filter cabinet to reduce pressure drop.

Why is my AC running but not cooling well?

Common causes include dirty filters or coils, blocked condenser airflow, low refrigerant charge from a leak, an iced evaporator, or duct leaks. Start with a fresh filter and clear debris around the outdoor unit; if results don’t improve, call a licensed technician to check pressures, superheat/subcool, and duct static pressure.

Is R‑410A being phased out?

Many regions are phasing down high‑GWP refrigerants, including R‑410A. New A2L options such as R‑32 or R‑454B are entering the market. Timelines differ by country; consult local regulations and your installer.

Do I really need annual maintenance?

Yes. A professional visit typically includes coil cleaning, electrical testing (capacitors, contactor), refrigerant charge verification, drain clearing, and airflow assessment. Preventive maintenance usually costs less than emergency repairs and can lower energy use.

Conclusion: Put Knowledge into Action and Make Your AC Work Smarter

We explored the essential components, their roles in the refrigeration loop, and how airflow, controls, and refrigerants shape comfort and cost. The compressor, condenser, expansion device, and evaporator handle the core cooling. Airflow—driven by the blower, protected by clean filters, and delivered through tight, insulated ducts—keeps efficiency high. With smart controls and thoughtfully chosen refrigerants, your system runs quieter, steadier, and cheaper.

Ready for quick wins? Try three steps today: 1) Inspect and replace your air filter; 2) Clear 60–90 cm (2–3 feet) around the outdoor condenser and gently rinse the coil; 3) Pour a small amount of diluted vinegar into the condensate drain to deter clogs. Next, schedule a professional tune‑up to verify charge, confirm airflow, and assess duct leakage. If the system is older or oversized, discuss variable-speed options and low‑GWP refrigerants. For many homes, duct sealing or adding a return delivers bigger comfort gains than replacing equipment—and costs less.

Your comfort, bills, and indoor air quality improve when the pieces work in harmony. Keep a simple maintenance checklist on your phone, set filter reminders, and photograph equipment labels and wiring so a pro can help quickly if issues pop up. Small habits add up to fewer breakdowns and cooler rooms on the hottest days.

The best time to optimize your AC is before the next heat wave. Take one step today, feel the difference when you tap the thermostat tomorrow. What will you do first?

Helpful Resources (Outbound Links):

– U.S. DOE Energy Saver: Air Conditioning Basics

– U.S. EPA: Refrigerant Management (Section 608)

– ASHRAE Technical Resources

– ENERGY STAR: Cooling Tips

– IEA: The Future of Cooling

Sources:

– U.S. Department of Energy, Energy Saver: Air Conditioning Basics and Maintenance Guides.

– U.S. Environmental Protection Agency: Refrigerants, Section 608, and GWP references.

– ASHRAE Fundamentals and Handbook references for airflow, duct design, and refrigerants.

– International Energy Agency (IEA): Cooling demand trends and efficiency pathways.

– ENERGY STAR and utility program data on duct leakage and filter maintenance impacts.